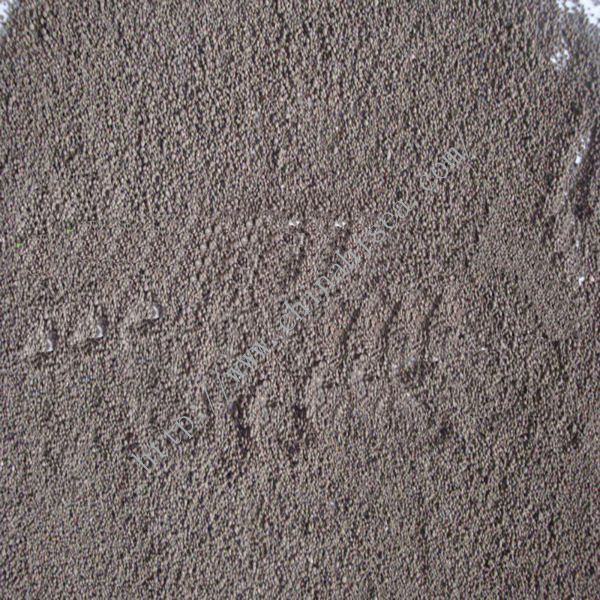

D102 surfacing welding rods

D102

GB:EDPMn2-03

AWS:

Current:Used for surfacing welding or repairing of the surfaces of worn-out low-carbon, medium-carbon and low-alloy steel parts, such as axles, gears, blades of mixers, etc.

AWS:

Current:Used for surfacing welding or repairing of the surfaces of worn-out low-carbon, medium-carbon and low-alloy steel parts, such as axles, gears, blades of mixers, etc.

D102 |

According with GB EDPMn2-03 |

||||||||

|

|

|||||||||

|

|

|||||||||

|

Chemical Composition of Deposited Metal (%)

|

|||||||||

|

Hardness of Surfacing Layer: HB≥220 |

|||||||||

|

Reference Current (AC, DC)

|

|||||||||

|

Instructions: 1.The electrodes must be baked under about 250℃ for an hour before welding. 2.Large work pieces should be preheated to about 200℃ before surfacing welding, and the rust and the oil stains on the surfaces of the welded parts should be cleared away. |

|||||||||

Society certificates

CONTACT WITH US NOW