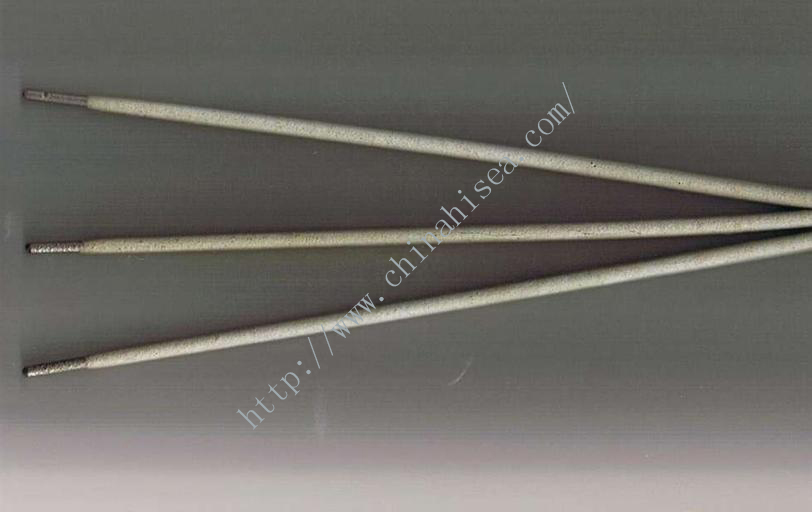

G307 stainless steel electrode

G307

GB:E430-15

AWS:E430-15

Current:Used for welding nitric acid corrosion-resistant and heat-resistant Cr17 stainless steel structures.

Main Applications:

AWS:E430-15

Current:Used for welding nitric acid corrosion-resistant and heat-resistant Cr17 stainless steel structures.

Main Applications:

G307 |

According with GB E430-15 Corresponding with AWS E430-15 |

||||||||||||||||||||

|

|

|||||||||||||||||||||

|

|

|||||||||||||||||||||

|

Chemical Composition of Deposited Metal (%)

|

|||||||||||||||||||||

|

Mechanical Properties of Deposited Metal (The temperatures of the test pieces should be preserved under 760-790℃ for an hour, and then they should be cooled along with the furnace to 595℃ at a speed of not higher than 55℃/h, and finally cooled in the air.)

|

|||||||||||||||||||||

|

Reference Current (DC+)

|

|||||||||||||||||||||

|

Instructions: 1.G307 electrodes must be baked under about 200-300℃ for an hour before welding. 2.The weldments should be preheated to 200℃ before welding, and tempered under 750-800℃ after welding. 3.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding. |

|

||||||||||||||||||||

Society certificates

CONTACT WITH US NOW