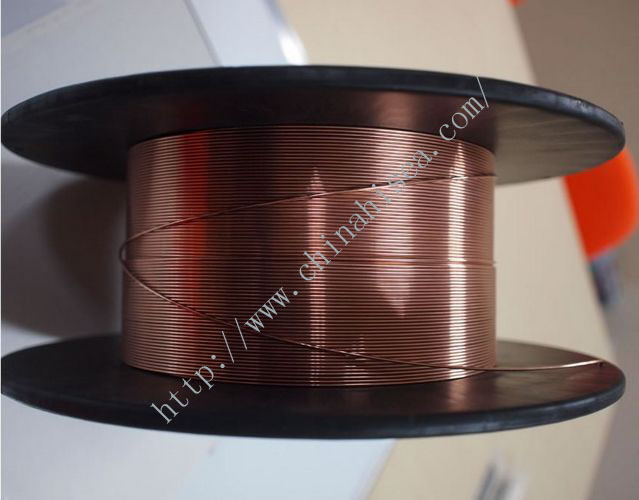

JQ.YR402 Gas-shielded Flux-cored Welding Wire

JQ.YR402

GB:E601T1-B3

AWS:E91T1-B3

Current:Suitable for welding 2.25��Cr��1��Mo steel below 520��.

Main Applications:

AWS:E91T1-B3

Current:Suitable for welding 2.25��Cr��1��Mo steel below 520��.

Main Applications:

JQ.YR402 |

According with GB/T 17493-1998 E601T1-B3 Corresponding with AWS A5.29 E91T1-B3 JIS Z3318 YF2CM-C |

||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||

|

Chemical Composition of Deposited Metal (%)(CO2Shielding Gas)

|

|||||||||||||||||||||||||

|

Mechanical Properties of Deposited Metal

|

|||||||||||||||||||||||||

|

Reference Current (DC+)

|

|||||||||||||||||||||||||

|

Instructions: 1.The oil stains and rust on the weldments should be cleared away. 2.When welding, the gas flow rate is generally 20~25L/min. 3.When welding with flux-cored welding wires, the extension elongation should be 15~25mm. 4.The humidity of the welding wire storerooms should be preserved below 60%. 5.It is not suitable for non-vacuum-packed welding wires to be stored for more than half a year, and it is not suitable for vacuum-packed welding wires to be stored for more than a year. |

|

||||||||||||||||||||||||

Society certificates

CONTACT WITH US NOW