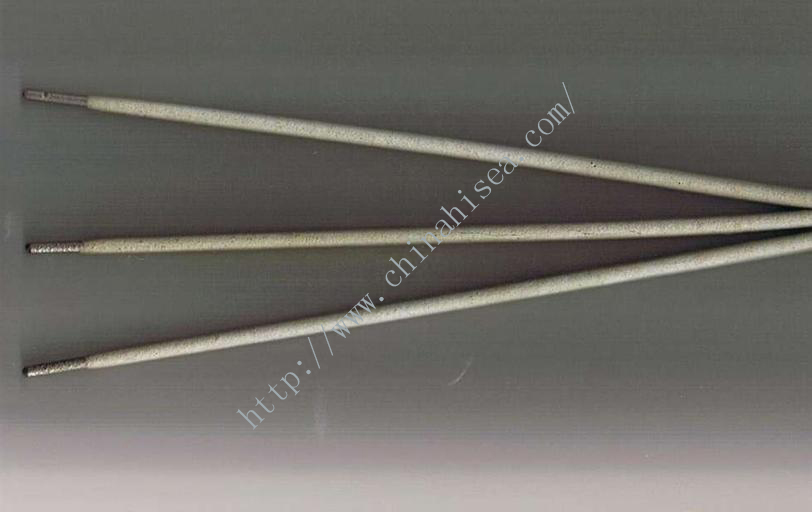

J506NiCu Corrosion-resistant Steel Electrode

J506NiCu

GB:E5016-G

AWS:

Current:Used for welding carbon steel and 490MPa tensile strength atmospheric corrosion-resistant steel structures, such as locomotive vehicles, offshore engineering, bridges, etc.

AWS:

Current:Used for welding carbon steel and 490MPa tensile strength atmospheric corrosion-resistant steel structures, such as locomotive vehicles, offshore engineering, bridges, etc.

J506NiCu |

According with GB E5016-G |

||||||||||||||||||

|

|

|||||||||||||||||||

|

|

|||||||||||||||||||

|

Chemical Composition of Deposited Metal (%)

|

|||||||||||||||||||

|

Mechanical Properties of Deposited Metal

|

|||||||||||||||||||

|

Diffusible Hydrogen Content in Deposited Metal: ≤6.0ml/100g(Glycerine Hydrogen Test) |

|||||||||||||||||||

|

X-ray Radiographic Inspection: ⅠDegree |

|||||||||||||||||||

|

Reference Current (AC, DC+)

|

|||||||||||||||||||

|

Instructions: 1.The electrodes must be baked under about 350℃ for an hour before welding, and used as soon as baking is completed. 2.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding. 3.When welding, short arc must be used and stringer bead is suitable. |

|||||||||||||||||||

Related products for "J506NiCu Corrosion-resistant Steel Electrode"

E7015-1 carbon steel welding rods

E7015-1 carbon steel welding rods JQ.H08E Submerged-arc Welding Wire

JQ.H08E Submerged-arc Welding Wire  G307 stainless steel electrode

G307 stainless steel electrode  JQ.YR402 Gas-shielded Flux-cored Welding Wire

JQ.YR402 Gas-shielded Flux-cored Welding Wire  W607 Low Temperature Steel Electrode

W607 Low Temperature Steel Electrode J502WCu Corrosion-resistant Steel Electrode

J502WCu Corrosion-resistant Steel Electrode JQ.MG50-6 Gas-shielded Solid Welding Wire

JQ.MG50-6 Gas-shielded Solid Welding Wire  AWS ENiCu-B Z508 cast iron welding rod

AWS ENiCu-B Z508 cast iron welding rod G302 AWS E430-16 stainless steel electrode

G302 AWS E430-16 stainless steel electrode  JQ.H00Cr19Ni12Mo2 Argon-arc Welding Wire

JQ.H00Cr19Ni12Mo2 Argon-arc Welding Wire

Society certificates

CONTACT WITH US NOW