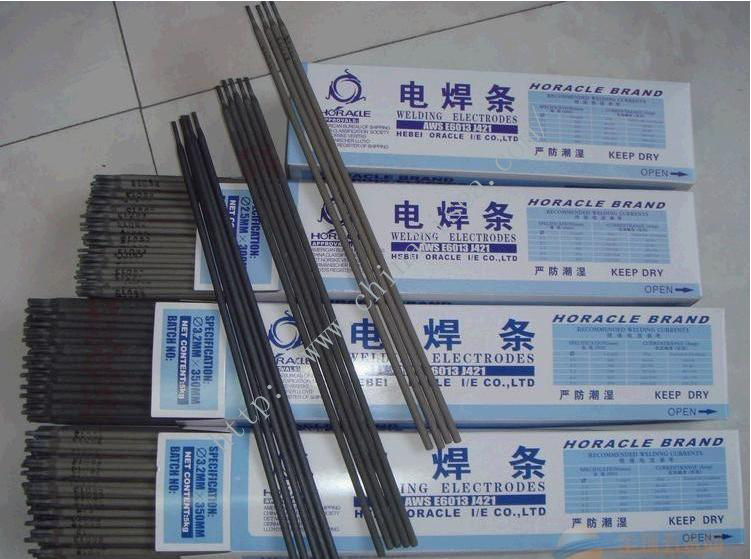

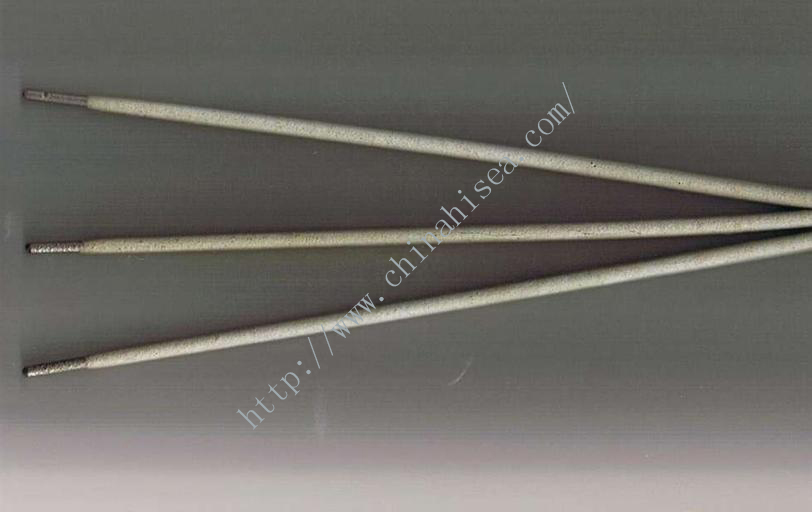

E7010 Pipe Welding Electrode

E7010

GB:E5010-G

AWS:E7010-G

Current:Used for butt welding of circumferential seam on all kinds of carbon steel pipes, and also suitable for vertical downward welding on general carbon steel structures.

AWS:E7010-G

Current:Used for butt welding of circumferential seam on all kinds of carbon steel pipes, and also suitable for vertical downward welding on general carbon steel structures.

E7010 |

According with GB E5010-G Corresponding with AWS E7010-G |

|||||||||||||||

|

|

||||||||||||||||

|

|

||||||||||||||||

|

Chemical Composition of Deposited Metal (%)

|

||||||||||||||||

|

Mechanical Properties of Deposited Metal

|

||||||||||||||||

|

X-ray Radiographic Inspection: ⅡDegree |

||||||||||||||||

|

Reference Current (DC+)

|

||||||||||||||||

|

Instructions: 1.The electrodes should be used as soon as they are unsealed. No need to bake. If the electrodes are affected with damp, they must be baked under 80℃ for 1.5 hours. 2.The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away before welding. 3.When welding, the current should not be too strong, and electrode weaving should not be too wide. |

|

|||||||||||||||

Society certificates

CONTACT WITH US NOW