- Home

- > Marine Equipment

- > Marine Auxiliary Machinery

- > Shot Blasting Machines

- > shot blasting machines

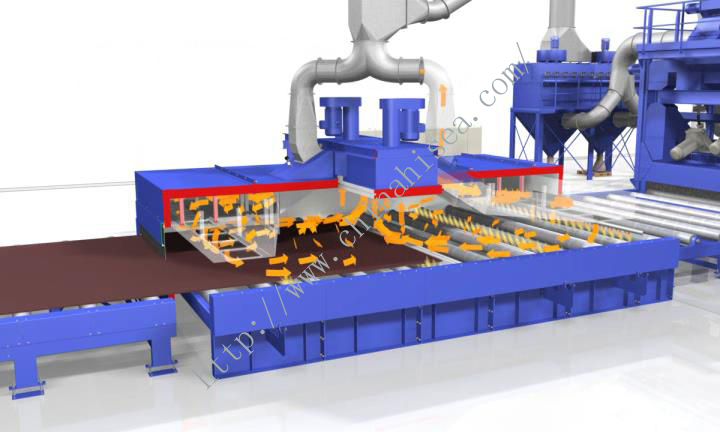

Automatic Environmental Pneumatic Recovery Sand Blast Room

Sand Blast Room:

Though cellular suck sand floors technical, pneumatic conveying principles and it generates negative pressure by vacuum pump to recover sand, then the sand is separated automatically from dust by separator unit built inside the equipment. The separated sand will be to the sand pressure tank again. The separated crushing sand, welding slag, scale cinder, stive will be to dust pelletizing system to filter. Meanwhile, there configured efficient cartridge filter for workers can see clearly. The stive will be inhaled out and then to filter.

The sand blast room containing blast room body, blasting and protective Equipment, sand recycle parts, separator part, hopper part, dust cleaning part, environmental noise reduction section, workpieces conveyor trolley part, and electrical equipments, etc., stive will be to dust pelletizing system to filter. Meanwhile, there configured efficient cartridge filter for workers can see clearly. The stive will be inhaled out and then to filter.

Technical Parameters:

|

No. |

Item |

Technical Standard |

|

1 |

Size of the Sand Blast Room(mm) |

8000(L)*2200(W)* 2500(H) |

|

The Structure of the Sand Blast Room |

Material: A. Body: Rectagular Steel Tube (80*40*2.5M) B. Wall: Fire insulation sandwich panel (50mm *16k*0.476) C. Protection: Wearable rubber sheet (3mm) |

|

|

Door Size(mm) |

2000(W)*2200(H) |

|

|

Door Structure |

Double, manual |

|

|

2 |

TS-900-2 sand blast machine |

A. Pressure sand blast tank: Hebei Wuqiao B. CLEMCO: U.S.A. C. Abrasive valve: U.S.A. D. Tee cut-off air control valve: Thomson, France |

|

Sand blast tank diameter |

900mm |

|

|

Sand blast tank volume |

0.8m3 |

|

|

Gun quantity |

2 sets |

|

|

Nozzle diameter |

φ10mm |

|

|

Speed per gun |

15-20m2/h |

|

|

Gas consumption per gun |

6.1m3/min |

|

|

3 |

Sand types |

Steel shot, quartz sand |

|

First Working Volume |

2000kg(steel shot) |

|

|

4 |

Workpiece conveyor trolley (1 set) |

Trolley moving power: 2.2kw Trolley rotating power: 1.5kw Sand moving power: 2.2kw |

|

5 |

Surface Quality |

Sa2.5(GB8923-88) |

|

6 |

Superficial density |

Abrasive roughness selection |

|

7 |

Illuminating System |

|

|

Light type |

Explosion-proof light |

|

|

Light quantity |

8sets |

|

|

Light power |

3kw |

|

|

8 |

Sand and dust separator |

|

|

Separate type |

two stages |

|

|

Separate size |

Stepless |

|

|

The amount of separation |

10T/h |

|

|

9 |

|

A. Main tank body: Q235 (thickness:4mm) B. Dust filter cartridges: Polyester fibre (Φ325mm-1000mm, 12pcs, power area 10.4m2/pc) C. Right-angle pulse valve: DCF-2L (automatic) D.Pulse control device jet dust individually though control the electromagnetic pulse valve |

|

Airflow |

Flow:7728-15445, Total Pressure:3187-2019 |

|

|

Filter wind speed |

0.4-0.8m/min |

|

|

Filter type |

Filter cylinder |

|

|

Shaker style |

Pulse cleaning |

|

|

Air consumption of cleaning |

0.3m3/min |

|

|

Collection efficiency |

99.99% |

|

|

Dust blower |

4-72-NO5.0A-15Kw (1 set) |

|

|

10 |

Sand recycling system |

A. Body tank: Q235 (thickness: 4mm) B. Dust filter cartridges: Polyester fibre (Φ325mm-660mm, 24pcs, power area 8.4m2/pc) C. Right-angle pulse valve: DCF-2L (automatic) D.Pulse control device jet dust individually though control the electromagnetic pulse valve. E. Honeycomb floor: Q235 (thickness: 3mm) F. Sand recycle sidle pipe: quarter bend (400mm*120mm*6mm) G. Sand recycle main pipe: quarter bend (400mm*300mm*6mm) Remarks:Because the rectangular tube, so the pipes cannot be banked –up. There is a sieve in the inlet to forbid big sundries into the pipe. |

|

Airflow |

Flow:12518-14913 Total pressure:2895-3436 |

|

|

Filter type |

Filter cylinder |

|

|

Suction sand fan |

9-26-9D, 15kw |

|

|

11 |

Dust discharge |

<100mg/m3 |

|

12 |

Noise level |

<85dB |

|

13 |

Illuminancy |

≥300Lux |

|

14 |

Electrical equipment |

PLC: Mitsubishi Other: Shredder |

|

15 |

Chimney |

Φ400*9000*3mm |

|

16 |

Total Power |

39kW ( air compressor except) |

Cross-section Drawing

Detail Parts of the Room

Society certificates

CONTACT WITH US NOW