- Home

- > Marine Equipment

- > Marine Auxiliary Machinery

- > Shot Blasting Machines

- > shot blasting machines

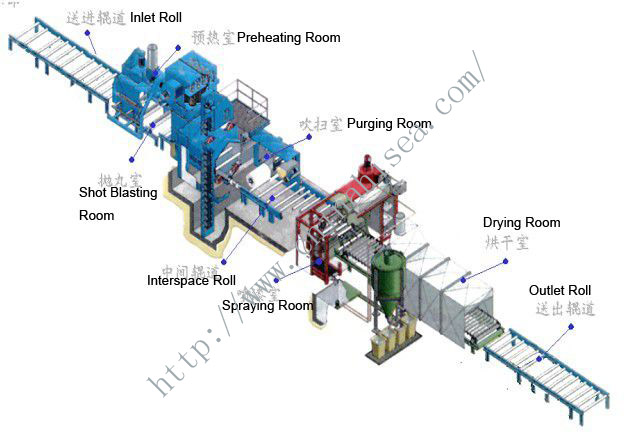

Horizontal Movable Shot Blasting Machine

The portable shot blast cleaning

machine is environment-friendly and has a low cost. It adopted the walk-behind

shot blasting system. The walk-behind shot blasting systems use a high

performance, airless, centrifugal wheel for propelling blast media at a high

velocity to the concrete and steel surface to clean it. The portable shot

cleaning machine is devided into two sorts: The horizontal machine and the

vertical machine. Whether it be a horizontal or vertical machine, it can be

quickly dissembled and fixed in only 20 minutes.

Horizontal Machines are mainly used

to remove paint, pitch and floating oil and clean highways, airport runways,

ship board, oil tank and bridges and other large asphalt surfaces. It is

electrically-powered, self-propelled and offers variable travel speed control to

provide a consistent blast pattern.

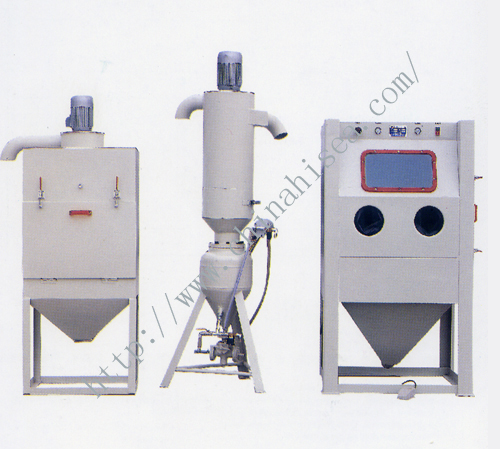

The concrete dust is recovered by a

powerful dust collection system. The dust collector removes pulverized abrasive,

dust and contaminants. Very little abrasive is lost and the usable media is

returned to the storage hopper for recirculation by the blast wheel. Vertical

Machines are designed to clean oil tanks, ship hulls and repair water tanks,

also to clean both sides of spherical objects and the roof of dome buildings. In

the vertical mode, a Hoist System, mounted on a powered Fixture at the top of

the structure being cleaned, raises and lowers the Blast Module as the module

and fixture traverse horizontally. The operator controls the machine movement,

hoist operation, and blast functions from the hand-held Wireless Remote Control,

thus making it possible to automatically recycle the abrasive media and non-stop

feed. It is very convenient because only one worker is enough to control the

operation. It saved labor and enhanced productivity. The abrasive media is

contained, circulated, and cleaned within the Blast Module. A vacuum hose with a

drum automatically deposits the paint and dust and easily disposes wastes. The

shot cleaning greatly lowerd the cost to only several cents cost per square

meter.

Shot blasting is the Professionals preferred solution:

1 To regenerate grip and improve safety on roads2 To remove old coatings, rubbers on airports

3 To remove marking on roads, highways, runways, industrial floors

4 To clean and prepare surfaces before applying a coating / paint / resin / tiles

Technical Parameters:

|

Type

|

ZPX75 | ZPX110 | ZPX150 | ZPX110D | ZPX150D |

| Working Width (mm) | 200 | 250 | 300 | 600 | 800 |

| Blasting Capacity (m2 /h) | >80 | >180 | >280 | >400 | >600 |

| Wheel Power (kw) | 7.5 | 11 | 15 | 2×11 | 2×15 |

| Machine Weight (kg) | 180 | 250 | 360 | 560 | 780 |

| Appropriate Dust Collector | include | include | include | include | include |

The Testing Showing:

Society certificates

CONTACT WITH US NOW