Supporting roller

Supporting roller

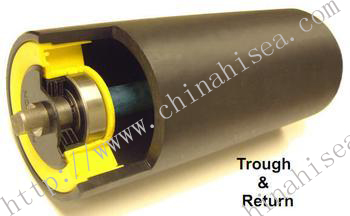

Supporting roller,also named as touch roll, cradle roll or idler, is an important part of the belt conveyor.It’s function is to support the belt and material weight, reduce the belt running resistance, and make the belt verticality does not exceed a certain limit in order to ensure the smooth operation of the belt. It accounts for 35% of the total cost of a belt type conveying mechanism and produces more than 70% of the resistance to the conveying mechanism, so the quality of supporting roller is particularly important.

Supporting roller must be flexible and reliable when in operation to reduce friction between the roller and conveyor belt. Supporting roller plays key role for the whole life of conveying belt,which accounts for above 25% of the total cost of the conveying mechanism. Although supporting roller in belt conveyor is a small part, its the structure not complicated, but producing high-quality roller is not easy.

Generally,they are used in great amount in conveying mechanism.Supporting roller has many varieties of kinds.

According to its material,supporting roller is distinguished into steel and non steel (such as rubber roller, ceramic roller, nylon roller and insulation roller) rollers.According to their use, supporting roller is divided as self-aligning roller, buffer roller, through type roller, parallel roller.

Self-aligning roller makes the role of correcting belt conveyor’s deviation.Usually, rotary trough aligning roller is installed onto the conveyor’s heavy section, parallel self-aligning roller installed onto the conveyor’s no-load segment.

According to the actual conditions, buffer roller is used onto the machine frame.When feeding material, these rollers can reduce impact the material brings to the belt, which is beneficial to the long service life of the belt.

Trough type roller generally consists of two side rollers and a pinto roller, with slot angle of 30 degrees in usual.For demountable belt conveyor,these three rollers are hinged to each other, so through type roller is also called hinged idler.

Parallel roller is generally a long roll, which is arranged onto a conveyor’s lower end which endures pressure,so it is also called the lower supporting roller.

Criteria to judge good or bad rollers are: roller radial runout; roller flexibility; roller axial momentum.

In addition, the following factors are important for supporting roller’s quality performance:

1.roller dustproof performance;2.roller waterproof performance;3.roller axial bearing properties;4 roller anti-impact performance;5.roller service life.

Effect of roller radial runout to belt conveyor: within the specified runout range, the belt machine can keep running smoothly, otherwise it will make the conveyor belt resonance beating, resulting in material spilling, polluting of the environment.So the higher belt speed, the smaller radial runout amount there should be to do benefits. China national standard of radial runout is 0.7 mm, the Japanese JIS standard specifies 0.5 mm.

Flexibility of the roller to conveyor: in the belt conveyor’s running, if roller’s flexibility not good, the belt conveyor system would have to pay a higher power under high spin drag coefficient,consume more power,sometimes tape tearing, motor burning will be caused, more seriously, even fire may be caused. Therefore, use of roller of low rotational drag coefficient (preferably less than 0.020) is an important part for belt conveyor design and selection.

Effect of axial movement to the belt conveyor: if the axial movement of idlers is too large, belt deviation can often appear, which will cause premature work failure to roller. The general axial movement control is desirably in 0.5-0.7 mm.

Roller’s sealing has steel and plastic branch. Their sealing method are of filling grease. Roller’s good or bad directly affects the service life of electric energy consumption and the belt conveyor. Therefore, dustproof and reliable seal, good lubrication are important use standard.

Roller parts: buffering rubber ring, bearing, bearing seat, sealing washers, stamping hook, clamp spring, roller shaft, retainer ring, elastic cylindrical pin, connector etc.

some highlights of our supporting rollers:

Ceramic roller: 1.effectively prevent deviation of conveyor belt, reduce the abrasion of the belt, extend service life of the belt 2.Because of its high temperature resistance, oxidation resistance, corrosion resistance,it is suitable for all kinds of environments. 3.It is suitable for coal mine environment for its static free, which means producing spark is not easy in wear collision.

Nylon roller: environmental temperature range of use: - 40 ℃ ~ 80 ℃. Its advantages are the following: 1.low friction coefficient,energy saving2.wear resistance, corrosion resistance, aging resistance, resistance to acid, alkali and organic solvent corrosion, no pollution 3.not easy to do damage to belt 4. good self-lubricating property, not easy to die without oil 5.can work in harsh environmental conditions. 6.antimagnetic and antistatic 7.withstand the repeated impact and vibration 8.dustproof & waterproof,can be used in dust environment 9.convenient installation, low repair rate,low noise, stable running 10.Nylon roller itself is light in weight(only 1/3 of weight of metal piece) but has long service life (3-5 times of service life of metal roller)

Trough type roller(groove roller):1.corrosion resistance( difficult to be corroded by acid alkali and salt) 2.high hardness & strong wear resistance. Trough type roller operates in full sealing state.Its two ends are protected with plastic labyrinth sealing ring to prevent oily grease leaking, so the rolling shaft can be in long-term use. 3. long service, 2-5 times of service life than steel roller 4. reducing repair time, reducing the comprehensive cost of belt conveyor.Trough type roller is widely used in large dust, high corrosive outdoor environment, such as mine, power plant, steel plant, stone material factory, cement plant, coal washery, salt, soda, chemical fertilizer factory, dock ,etc.

Ceramic surface trough type roller: 1.oxide film on the smooth , non adhesive materials in contact with the conveyor belt,small friction coefficient 2.reducing the winch driving force 3. preventing belt to off track 4.extending belt’s service life.

Buffer roller:.corrosion resistant, flame retardant, anti static,light weight,good abrasion resistance, good self lubrication.Buffer roller is used for relief of material feeding impact on the conveyor belt at the belt’s material receiving point. This roller type is mainly developed for mine,coal washing plant, coking plant, chemical plant and other corrosive environment.Its toughness is 10 times more than ordinary metal roller. Roller roller body and seals are made of special high polymer materials,its mechanical properties is similar to bronze, so the belt will not be hurt.Its service life can reach more than 5 times of the ordinary roller.

Our company’s roller type and model are complete, we accept customized need.

Society certificates

CONTACT WITH US NOW