Steel Wire Rope

1. Steel Wire Rope Brief Introduction

General speaking, the steel wire rope made of steel mainly.

1.1 Wire Rope

Wire rope, or cable, is a type of rope which consists of several strands of metal wire laid (or 'twisted') into a helix. Initially wrought iron wires were used, but today steel is the main material used for wire ropes.

Historically wire rope evolved from steel chains which had a record of mechanical failure. While flaws in chain links or solid steel bars can lead to catastrophic failure, flaws in the wires making up a steel cable are less critical as the other wires easily take up the load. Friction between the individual wires and strands, as a consequence of their twist, further compensates for any flaws.

1.2 Modern wire rope

Modern wire rope was invented by the German mining engineer Wilhelm Albert in the years between 1831 and 1834 for use in mining in the Harz Mountains in Clausthal, Lower Saxony, Germany. It was quickly accepted because it proved superior to ropes made of hemp or to metal chains, such as had been used before.

2. Steel Wire Rope Construction

The steel wire rope usually have three parts: Wire, Strand, and Core. As the below picture showing:

2.1 Wires

Steel wires for wire ropes are normally made of non-alloy carbon steel with a carbon content of 0.4 to 0.95%. The tensile forces and to run over sheaves with relatively small diameters.

2.2 Strands

In the so-called cross lay strands, the wires of the different layers cross each other. In the mostly used parallel lay strands, the lay length of all the wire layers is equal and the wires of any two superimposed layers are parallel, resulting in linear contact. The wire of the outer layer is supported by two wires of the inner layer. These wires are neighbours along the whole length of the strand. Parallel lay strands are made in one operation. The endurance of wire ropes with this kind of strand is always much greater than of those (seldom used) with cross lay strands. Parallel lay strands with two wire layers have the construction Filler, Seale or Warrington.

2.3 Cores

The core you can choose fiber, organics, cotton, rock wool, or steel wire. But different core different application.

2.3.1 The fiber core with better elastic and flexible. And it can store some lube. It is best choice for cranes.

2.3.2 The steel wire core, which is good for hyperthermal and multi-layer winding situation.

2.3.3 The rock wool core used for hyperthermal situation.

2.3.4 The organics core suit for un-hyperthermal situation.

3. The code of wire cores

| Item | Materials | Code |

| 1 | Fiber (natural or complex) | FC |

| 2 |

Natural fiber |

NF |

| 3 |

Complex Fiber |

SF |

| 4 | Steel wire | IWR/IWRC |

| 4 | Steel strand | IWS |

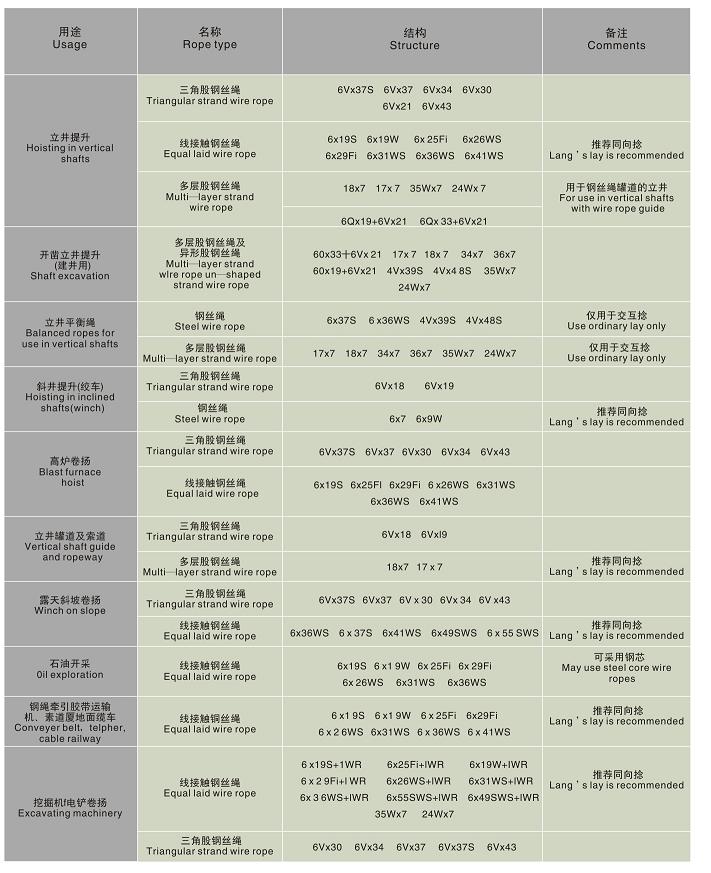

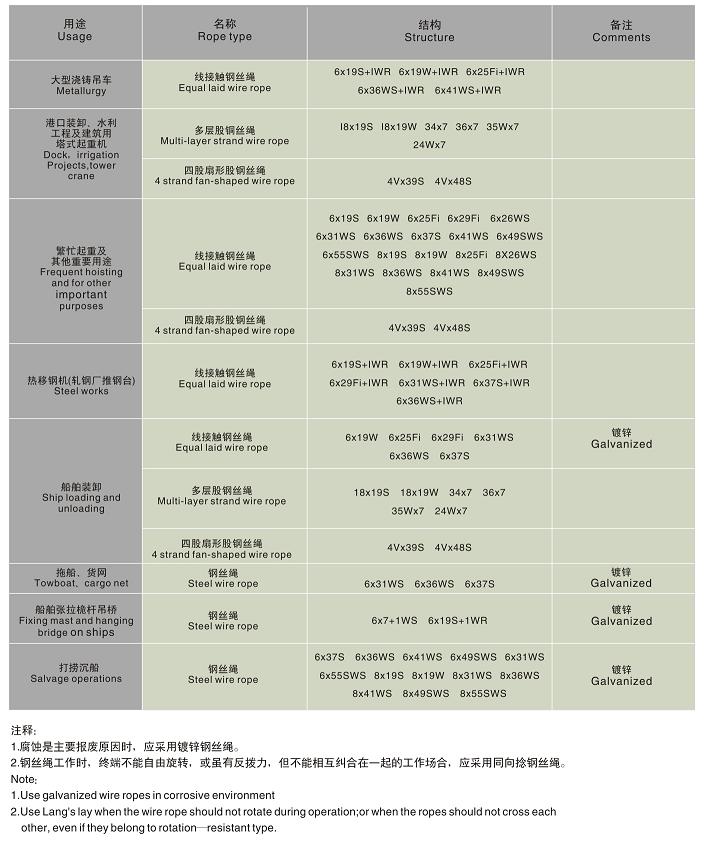

4. Steel Wire Rope Different Structures Different Application.

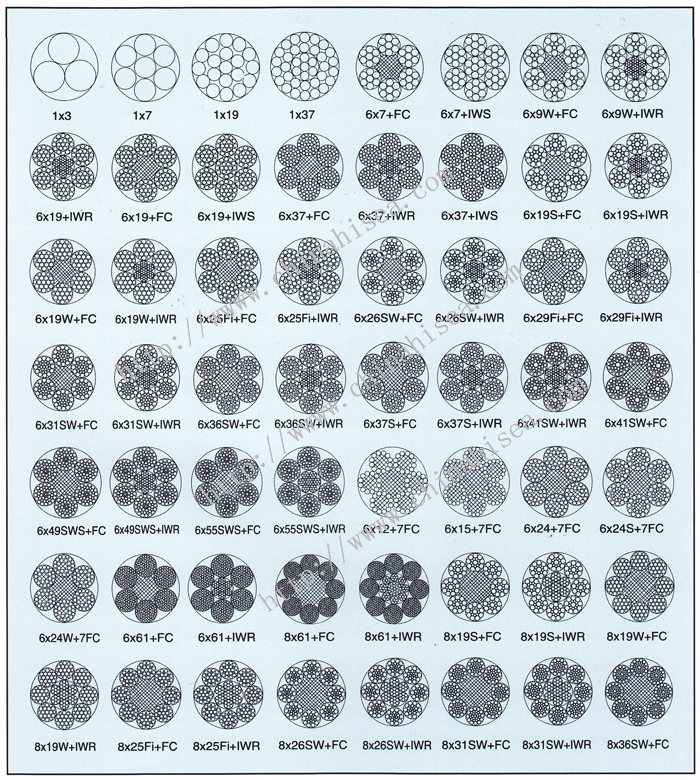

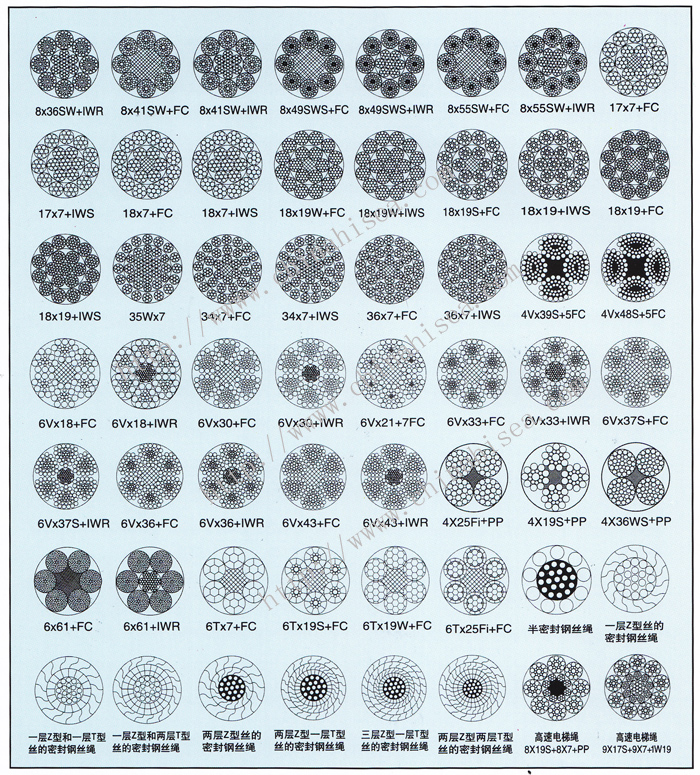

5. The Steel Wire Rope Models for you choose.

Society certificates

CONTACT WITH US NOW