Pipe Handling System

Features of Pipe Handling System:

PDC-100 Joint Hoist (Pipe Deck Crane):

A.PDC-100 joint hoist with unique modularized grab design ensures that it can properly grab a pipe under the condition that the clearance between pipes is very small.

B.The joint hoist has a working radius up to 25 m. The equipped three quick change grab module have a 2 7/8~30in grab pipe diameter in total, which can meet the requirements of offshore drilling processes.

C.PDC-100 joint hoist featuring action self-lock, overload protection, emergency action, pipe tilting monitoring and other functions ensures efficiency, stability, reliability and safety to the greatest extent.

TFM-200 Dynamic Catwalk (Catwalk/Tubular Feeding Machine):

A.TFM-200 dynamic catwalk can be operated from the driller control room or from an independent catwalk operation table. It is mainly designed for conveying drill pipe, drill collar and casing in the range diameter of 2 7/8~30 onto the derrick floor.

B.Catwalk is also equipped with equipment conveyor bracket, which helps convey drilling tools and equipment to the derrick floor.

C.The unique design of telescopic folding arm enables pipes to tilt certain degree so that it is easier for other equipment grabbing pipes. In addition, the folding arm stablize the casing in working.

AMH 100-10x45 Adjustable Mousehole:

A.AMH 100-10x45 adjustable mousehole, working in conjunction with other pipe handling equipment for connecting/removing stand, can be operated from the driller cabin..

B.Pipe centralizer device is also set on the upper part of the equipment to ensure accurate pipe center for easy make-up or other pipe handling equipment grabbing pipes. The equipment adopts hydraulic driven gear train traveling lifting system to ensure stable and reliable lifting.

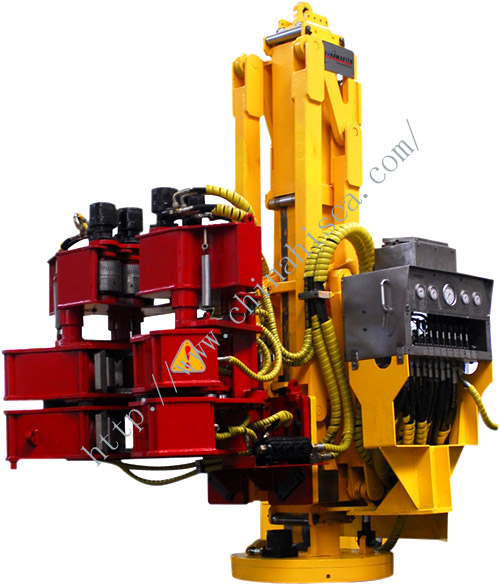

HVA-100 Stand Connection Manipulator (Horizontal/Vertical Arm):

A.HVA-100 stand connection manipulator control system realizes real-time monitoring of parameters and has the function of automatically locating positions of mouse hole and rat hole/

B.The unique design of clamp of HVA-100 stand connection manipulator ensures identical holding centers of pipes of different diameters. The clamp support mechanism is a unique design to ensure independence between operations of distance adjustment and gesture adjustment, which ensures accuracy and efficiency of positioning and make-up.

C.HVA-100 stand connection manipulator is equipped with pipe detection device and hydraulic bouncing device, increasing operation stability and reliability.

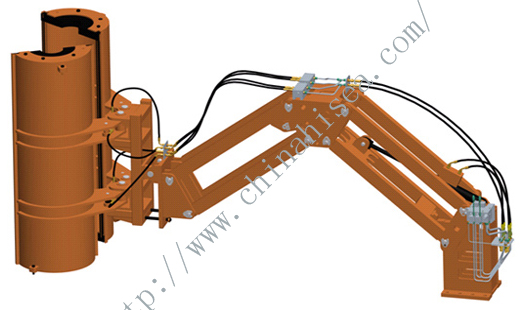

PRM-100 Pipe Racking Machine:

A.PRM-100 pipe racking machine adopts manipulator of parallelogram structure, without the necessity of clamp head gesture adjustment.

B.Pipe detection system and lifting bouncing system are equipped for easier operation, better stability, efficiency and reliability.

AB300x10 Aerial Work Basket:

A.AB300x10 aerial work basket mounted on derrick can be locally or remote operated. It can deliver operators to a height to maintain or service equipment or center the sleeve.

B.AB300x10 aerial work basket can rotate left and right, up and down, and the boom is retractable. During up-and-down swing of the telescopic boom, the manned basket is always horizontal. The equipment offers easy operation, safe and reliable running.

MB100 Mud Bucket:

A.MB100 mud bucket mounted on the derrick floor can be operated locally or from the driller control room.

B.It is applicable for extensive pipe diameters, easy for operation, and offers stable and reliable operation.

Specifications of Pipe Handling System:

PDC-100 Joint Hoist (Pipe Deck Crane)

|

Working conditions |

Working radius(m) |

Applicable pipe diameter(in) |

Safe working load (t) |

Body swiveling speed (r/min) |

Telescopic boom travel (m) |

System pressure (MPa) |

Total weight (kg) |

|

Temperature: -20℃~+40℃ Humidity: ≤100% |

3~25 |

2 7/8″~30″ |

3.5-25m 10 -12m |

0~1.2 |

2 |

31.5 |

39500 |

TFM-200 Dynamic Catwalk (Catwalk/Tubular Feeding Machine)

|

Applicable diameter range |

Working frequency |

Carrier safety load |

Folding arm safety load |

Carrier moving distance |

|

2 7/8″~30" |

40~60 pc/h |

200kN |

50kN |

8.6m |

|

Slideway length |

Trolley moving distance on slideway |

Folding arm lifting height |

Overall dimension |

Total weight |

|

16.7m |

13m |

2m |

18185mm×2900mm×6070mm |

25t |

AMH 100-10x45 Adjustable Mousehole

|

Maximum load (t) |

10 |

|

Applicable pipe length (m) |

8~13.7 |

|

Applicable pipe diameter (in) |

2 7/8~10 |

|

Maximum lifting speed (m/s) |

0.4 |

|

Maximum lifting travel (m) |

9 |

HVA-100 Stand Connection Manipulator (Horizontal/Vertical Arm)

|

Applicable pipe range |

Maximum applicable pipe length |

Maximum lifting load |

Horizontal extension range of tong |

|

2 7/8″~9 5/8″ |

14m |

10t |

700mm |

|

Horizontal swiveling angle of tong |

Vertical swiveling angle of tong |

Guide rail inner opening |

Hydraulic system pressure |

|

0°~40° |

0°~80° |

2.4m |

21MPa |

PRM-100 Pipe Racking Machine

|

Applicable pipe range (in) |

Clamper: 2 7/8~9 5/8 Dedicated hanging tong: 2 7/8~20 |

|

Maximum lifting load (t) |

10t -—3.1m 2.3t —3.2m |

|

Telescopic boom working range (m) (Relative swiveling center) |

0.715~4.085 |

|

Total weight (t) |

28 |

AB300x10 Aerial Work Basket

|

Safe working load |

Maximum reach distance |

Up-down swing angle |

Left-right swing angle |

Overall dimension |

Total weight |

|

300kg |

11m |

±60° |

±45° |

975mm×3170mm×5850mm |

2750kg |

MB100 Mud Bucket

|

Applicable drilling tool diameter |

Working range |

Reach distance |

Hydraulic control pressure |

Overall dimension |

Total weight |

|

3 1/2″~7″ |

1371~3249mm |

1878 mm |

16MPa |

1800*780*2166mm |

1300kg |

Pictures of Pipe Handling System:

Pipe Handling System

For further and more detailed product information, you are welcome to contact us at any time in any of the following ways.

---------------------------------

Contact:

Aiphen ZHANG

Sales Manager

Chongqing Hi-Sea Marine Equipment Import & Export Co., Ltd.

Address: Unit 20-5, Building of Chongqing General Chamber of Commerce, No.2, Hongjin Street, Yubei District, Chongqing 401147, China

E-mail: oildept@hiseamarine.com

Society certificates

CONTACT WITH US NOW