Marine Spark Proof Centrifugal Fan

1.General

CBGD series (explosion-proof) marine spark proof centrifugal fan (the fans) are explosion proof products which developed from CGDL series marine centrifugal fans. The series are designed and manufactured according to Marine Explosion-Proof Fans, Electrical Apparatus for Explosive Atmospheres and ship regulation of Chinese and international.

Non-sparking fans are suitable for ventilation of chamber which contains combustible and explosive gas. They are also applicable for other suitable places.

This series non-sparking fans have been examined and proved up to standard by the Explosion-proof Inspection Authority of the PRC and have got the certificate of inspection. They have also been examined by the Register of Shipping of PRC and have got the certificate.

2.Features

This series non-sparking fans have the feature of high explosion-proof grade, high efficiency, low noise, no overload, well anticorrosive, swing resistance, vibration resistance and shock resistance, stable running and safety, reliability etc.

3.Structure

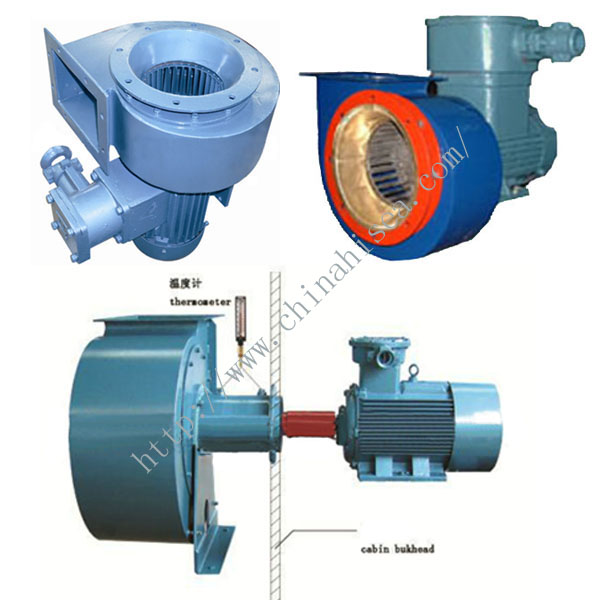

There are two structural type:

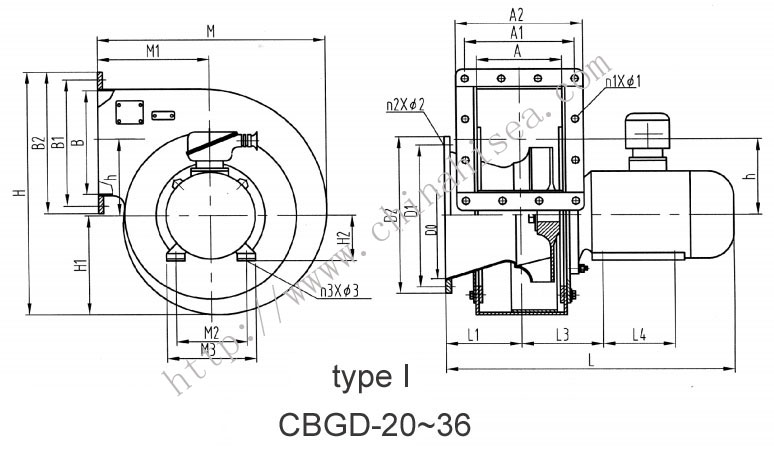

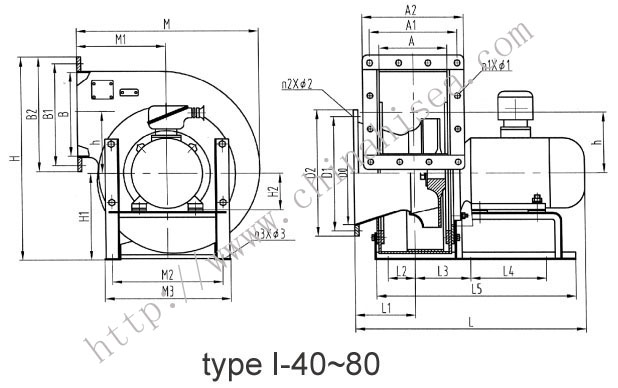

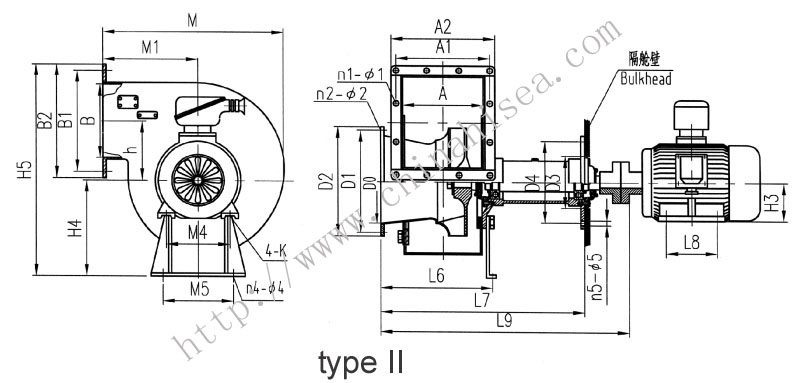

Type I (direct coupling type) and type II (separate cabins type). The construction is non sparking.

Type I is a motor direct coupling one, on the motor shaft the impeller is mounted directly, and the casing is fixed on the flange of the explosion-proof motor. Type II is separate structure, the fan and the motor are separated. It consists of fan driving device, flexible coupling and motor. The driving device consists of body bearing, bearing, shaft, brass rings and glands. It can be oiled and measured the temperature. One side is fixed on the fan and the other side will be mounted on the bulkhead.

The fan may be made into a horizontal, single-stage, single-suction and airtight structure, it also can be made into vertical type.

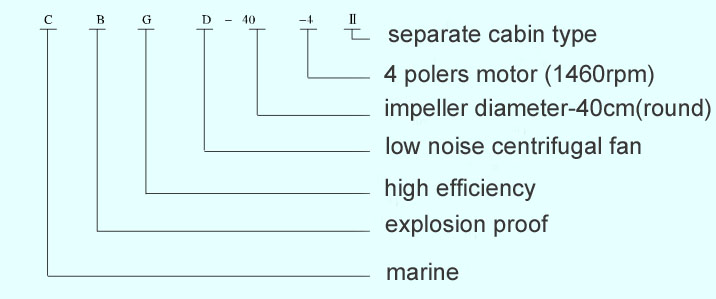

4.Code of the Model Explanation(The impeller diameter from 20cm to 80cm )

5.drawing of this marine centrifugal fan (type I -20~36 type I -40~80 and type II )

6.Parameters and Outline Size(From CBGD-20 to CBGD-40 for Reference)

|

CBGD-20-2 |

400 600 800 |

500 430 275 |

550 490 360 |

2920 |

50 |

0.75 |

1.5 |

YB801-2-H |

YB90S-2-H Y90S-2-H |

45 |

73 |

|

600 800 1000 |

700 560 360 |

760 650 410 |

3500 |

60 |

|||||||

|

CBGD-25-2 |

800 1100 1500 |

710 600 380 |

760 670 510 |

2920 |

50 |

0.75 |

1.5 |

YB801-2-H |

YB90S-2-H Y90S-2-H |

47 |

75 |

|

1000 1400 1800 |

1010 830 550 |

1090 940 730 |

3500 |

60 |

|||||||

|

CBGD-28-2 |

1000 1600 2200 |

900 750 460 |

930 820 610 |

2920 |

50 |

0.75 |

1.5 |

YB801-2-H |

YB90S-2-H Y90S-2-H |

50 |

78 |

|

CBGD-32-2 |

1600 2200 3000 |

1230 1080 740 |

1270 1170 890 |

2920 |

50 |

1.1 |

1.5 |

YB802-2-H |

YB90S-2-H Y90S-2-H |

58 |

86 |

|

CBGD-32-4 |

900 1200 1500 |

290 240 180 |

310 270 220 |

1460 |

50 |

0.55 |

1.1 |

YB801-4-H |

YB90S-4-H Y90S-4-H |

58 |

86 |

|

1000 1400 1800 |

420 360 260 |

440 390 320 |

1750 |

60 |

|||||||

|

CBGD-36-2 |

2400 3300 4200 |

1560 1370 1070 |

1630 1490 1260 |

2920 |

50 |

2.2 |

2.2 |

YB90L-2-H |

YB90L-2-H Y90L-2-H |

64 |

91 |

|

CBGD-36-4 |

1400 1800 2200 |

370 330 230 |

390 360 280 |

1460 |

50 |

0.55 |

1.1 |

YB801-4-H |

YB90S-4-H Y90S-4-H |

61 |

88 |

|

1400 1900 2500 |

570 510 400 |

590 560 480 |

1750 |

60 |

|||||||

|

CBGD-40-2 |

4000 5500 7000 |

1960 1570 1000 |

2080 1790 1360 |

2920 |

50 |

4 |

4 |

YB112M-2-H |

YB112M-2-H Y112M-2-H |

123 |

146 |

|

CBGD-40-4 |

2000 2800 3500 |

480 39-0 260 |

510 450 350 |

1460 |

50 |

0.75 |

1.1 |

YB802-4-H |

YB90S-4-H Y90S-4-H |

88 |

115 |

|

2400 3200 4200 |

700 590 380 |

730 670 510 |

1750 |

60 |

1.1 |

1.1 |

YB90S-4-H |

101 |

More informations, please feel free to contact us!

Society certificates

CONTACT WITH US NOW