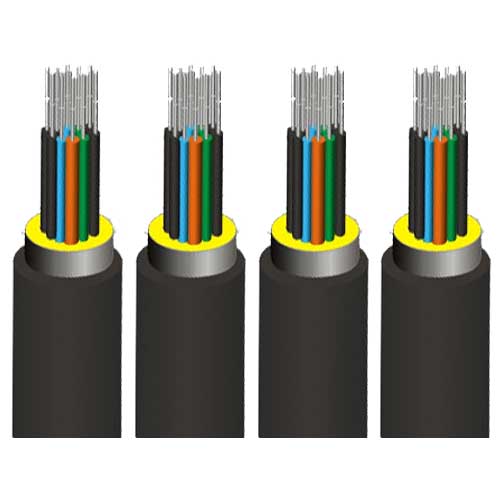

Loose tube stranded fiber optic cable

Loose tube stranded fiber optic cable description

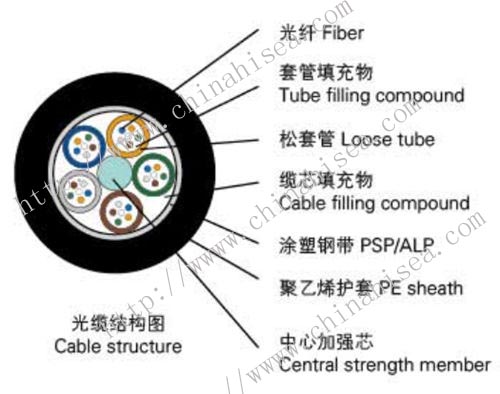

The fibers,250μm,are positioned in a loose tube made of a high modulus plastic,the tubes are filled with a water-resistant filling compound.A Steel wire,sometimes sheathed with polyethylene(PE) for cable with high fiber count,locates in the center of core as a metallic strength member.Tubes and fillers are stranded around the strength member into a compact and circular cable core.An Aluminum Polyethylene Laminate(APL) is applied around the cable core,which is filled with the filling compound to protect it from water ingress.Then,the cable is completed with a PE sheath.Application:Duct,Aerial

Loose tube stranded fiber optic cable Characteristics

1.Good machanical and temperature performance

2.High strength loose tube that is hydrolysis resistant

3.Special tube filling compound ensure a critical protection of fiber

4.Special designed compact structure is good at preventing loose tube from shrinking

5.PE sheath protects cable from Ultraviolet radiation

6.The following measures are taken to ensure the cable is water tight

- Steel wire used as the central strength member

- Loose tube filling compound

- 100% cable core filling

- APL moisture barrier

Loose tube stranded fiber optic cable Technical parameters

| Fiber optic cable model incremented by 2 | Fiber Number | Diameter(mm) | Weight(kg/km) | Tensile strength(Long/Short)N |

Allowable pressure flat force(Long/Short)N |

Bending radius(Static/Dynamic)mm |

| GYTA/S-2~6Xn | 2~12 | 9.5 | 80 | 600/1500 | 300/1000 | 10D/20D |

|

GYTA/S-8~12Xn |

2~12 |

9.5 | 80 | 600/1500 | 300/1000 | 10D/20D |

|

GYTA/S-14~18Xn |

14~24 |

9.5 | 80 | 600/1500 | 300/1000 | 10D/20D |

|

GYTA/S-20~24Xn |

26~36 |

9.5 | 80 | 600/1500 | 300/1000 | 10D/20D |

|

GYTA/S-26~30Xn |

26~36 |

9.5 | 80 | 600/1500 | 300/1000 | 10D/20D |

|

GYTA/S-32~36Xn |

38~48 |

9.7 | 97 | 600/1500 | 300/1000 | 10D/20D |

Loose tube stranded fiber optic cable construction

Society certificates

CONTACT WITH US NOW