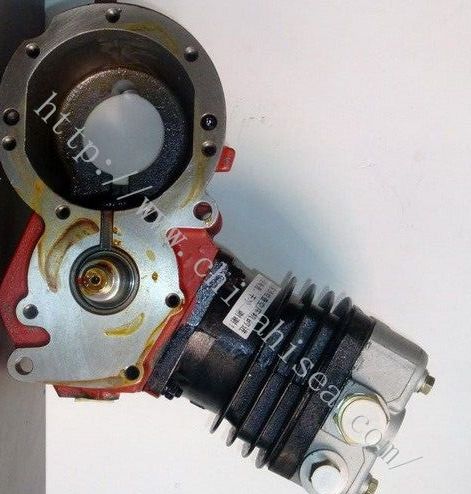

Deutz Cylinder Block 1013&2012

Deutz Cylinder Block 1013&2012:

1) Original material standard according to the original OEM technical drawing

2) Premium quality standard guaranteed

3) FREE sample possible acceptable

4) Long lasting and reliable working life time

5) Positive customer feedback from abroad and domestic market

6) Long exporting history to EUROPE, MIDDLE EAST, and SOUTH ASIA

7) Competitive and reasonable price level

8) Able to develop & produce according to your specification with technical drawing

9) Unique DALAI Packing or packing according to customer specification requirement

10) Flexible and convenient logistic service in CHINA & EUROPE

11) Our own branch with Distributing STOCK IN EUROPE

12) Multi-language communication in Chinese, Russian, German, English, French

13) Providing product Guarantee Period

14) R&D development capacity provided by experts and technician

15) We are doing SAFE & FAIR BUSINESS

Deutz 1013 & 2012 OEM cylinder block A cylinder block is an integrated structure comprising the cylinder(s) of a reciprocating engine and often some or all of their associated surrounding structures (coolant passages, intake and exhaust passages and ports, and crankcase). The term engine block is often used synonymously with "cylinder block" (although technically distinctions can be made between en bloc cylinders as a discrete unit versus engine block designs with yet more integration that comprise the crankcase as well).

In the basic terms of machine elements, the various main parts of an engine (such as cylinder(s), cylinder head(s), coolant passages, intake and exhaust passages, and crankcase) are conceptually distinct, and these concepts can all be instantiated as discrete pieces that are bolted together. Such construction was very widespread in the early decades of the commercialization of internal combustion engines (1880s to 1920s), and it is still sometimes used in certain applications where it remains advantageous (especially very large engines, but also some small engines). However, it is no longer the normal way of building most petrol engines and diesel engines, because for any given engine configuration, there are more efficient ways of designing for manufacture (and also for maintenance and repair). These generally involve integrating multiple machine elements into one discrete part, and doing the making (such as casting, stamping, and machining) for multiple elements in one setup with one machine coordinate system (of a machine tool or other piece of manufacturing machinery). This yields lower unit cost of production (and/or maintenance and repair).

Today most engines for cars, trucks, buses, tractors, and so on are built with fairly highly integrated design, so the words "monobloc" and "en bloc" are seldom used in describing them; such construction is often implicit. Thus "engine block", "cylinder block", or simply "block" are the terms likely to be heard in the garage or on the street.

Society certificates

CONTACT WITH US NOW